定位器

智能閥控制器 ND9000

-

?回轉(zhuǎn)及有線驅(qū)動(dòng)器兼用

?依TüV有SIL 2認(rèn)證(IEC 61508基準(zhǔn))

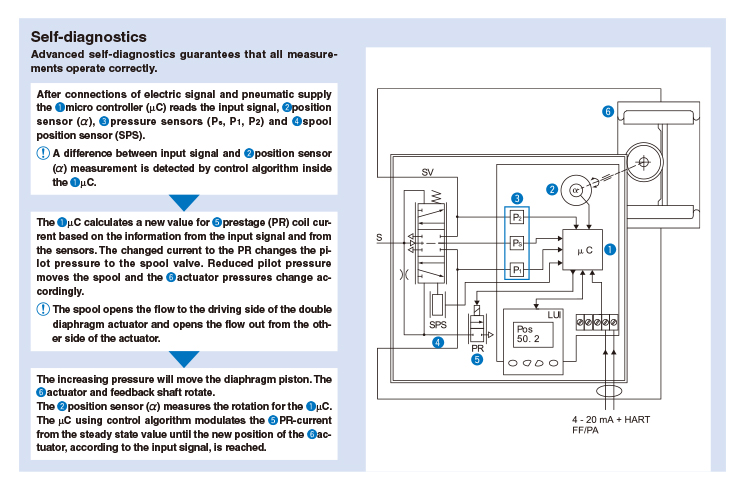

?搭載多彩的自己診斷功能

?搭載故障安全功能(全閉/全開)

?HART通訊對(duì)應(yīng)

?外殼: IP66, NEMA 4X

| 系列 | 外殼材質(zhì) | 空氣連接口 | 供給壓力 (MPa) | 供給電力 |

|---|---|---|---|---|

| ND9100 | 陽極酸化鋁合金 及聚合物複合材 | G1/4 | 0.14 ~ 0.8 | 4 ~ 20 mA |

| ND9200 | 陽極酸化鋁合金 及強(qiáng)化玻璃 | NPT1/4 | 0.14 ~ 0.8 | 4 ~ 20 mA |

| ND9300 | 不鏽鋼 | NPT1/4 | 0.14 ~ 0.8 | 4 ~ 20 mA |

| ND9400 | 不鏽鋼 及聚合物複合材 | NPT1/4 | 0.14 ~ 0.8 | 4 ~ 20 mA |

產(chǎn)品特點(diǎn)

?Benchmark control performance on rotary and linear valves

?Reliable and robust design

?Easy commissioning and operation

?Safety; SIL 2 certified by TüV (Acc. to IEC 61508)

?Language selection: English, German and French

?Local/remote operation

?Expandable architecture

?Equipped with a variety of self-diagnostics

Self-diagnostics/Online diagnostics/Performance diagnostics/Communication diagnostics/

Extended off-line tests/Performance view/Online Valve Signature

?Linearisation of the valve flow characteristics

?Excellent dynamic and static control

performance

?Fast response to control signal change

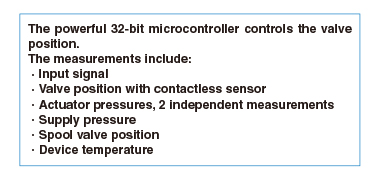

?Accurate internal measurements

?Can be used for linear and rotary valves,

double and single acting actuators

?Simple fast calibration and configuration

using Local User Interface (LUI)

using DTM / EDD in a remote location

using DCS asset management tools

?Low power consumption enables installation

to all common control systems

?Interchangeable communication options:

HART 6 or 7 (H)

FOUNDATION fieldbus

Profibus PA

?Limit switches

?Position transmitter (in HART only)

?Full stainless steel enclosure

?Exhaust adapter

?Remote mounting

?Arctic temperature specifications: (Up to –53°C)

?The ND9000 can be freely interfaced with software and hardware from a variety of

manufacturers. Using this open architecture allows the ND9000 to be integrated with other field

devices to give higher controllability.

?FDT and EDD based multi-vendor support configuration

?Support files for ND9000 are available at the following website: www.neles.com/valves

?Interoperability

Host interoperability

FOUNDATION fieldbus ITK version 6.1.2

Profibus PA profile version 3.0 PNO

?Easy to upgrade; by replacing the HART communication board with a fieldbus communication

board

?Excellent maintainability with firmware download feature

?Advanced communication diagnostics

?Digital communication via the fieldbus includes not only the set point, but also the position

feedback signal. from the position sensor. No special supplementary modules for analog or

digital position feedback are needed when using the fieldbus valve controller.

?Back up LAS functionality available in FOUNDATION fieldbus environment

?Input selector and output splitter blocks available in FOUNDATION fieldbus devices allowing

advanced distributed control

?Standard function blocks enables the freedom to use the ND9000 intelligent valve controller in

either continuous or on-off control applications

?Open and close information is directly available via the fieldbus

?Open and close detection is based on either position measurement (soft limit switch) or

mechanical limit switch information

?Can be mounted on single and double-acting actuators

?Both rotary and linear valves

?Ability to attach options to electronics and mechanics later

?1-point calibration feature enables mounting without disturbing the process

?Designed to operate in harsh environmental

conditions

?Rugged modular design

?Excellent temperature characteristics

?Vibration and impact tolerant

?IP66 enclosure

?Stainless steel enclosure

(ND9300 and ND9400)

?Protected against humidity

?Wear resistant and sealed components

?Contactless position measurement

?Easy access to collected data with Metso

Device Care software

?Unique Online Valve Signature to detect valve

friction even more accurately.

?Performance view with report, which gives

guidelines for recommended actions.

?Logical trend and histogram collection

?Information collected during process uptime

?Extensive set of off-line tests with accurate

key figure calculations

?Fast notifications with on-line alarms

?Condition monitoring tool available

?Real time monitoring of valve control

parameters